Laboratory Application:

In March our customer said: “We are most likely going to soon order 1 of the AHP-301CPV.”

First though, can you please provide a quote on the manufacture of a top plate? We would like to fit:

- 2 x 500 mL Schott bottles (the one I measured was 86mm diameter)

- 2 x 250 mL Schott bottles (the one I measured was 68mm diameter)

- 2 x 50 mL Schott bottles (the one I measured was 46mm diameter)

I’d guess that Schott do not make their bottles to too tight specifications, so we would need to allow some room for tolerances. What do you think? These could be arranged in any way that fit best and that minimized any top plate overhang over the cold plate beneath. We can foresee out-growing the 50 mL bottles, so ideally would like the ‘walls’ surrounding the 50 mL wells to be thick enough to later be drilled out so that the wells can accommodate 100 mL Schott bottles (the one I measured was 56mm diameter). The height of the top plate (i.e. depth of the wells) only need be about 70 mm. For the current application, we only need to chill to about 5 deg °C. Does the range we are interested in affect anything?

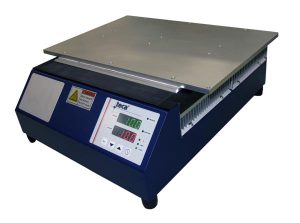

In May we shipped the custom “Beaker Block: and AHP-301CPV.