Donation of Recirculating Liquid Chiller:

TECA is pleased to be a part of an educational exhibit in a science museum.

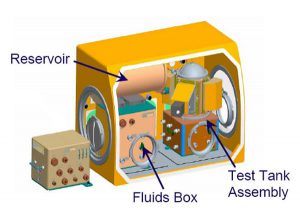

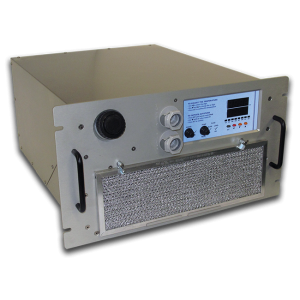

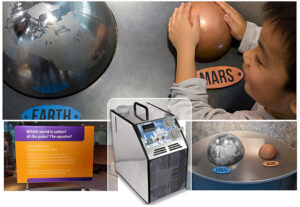

TECA donated a TLC-700, our most popular model of Recirculating Liquid Chiller to the New York Hall of Science (NYSCI). The TLC-700 is part of the “Search for Life” exhibition. Specifically, it cools Mars and The North Pole in an exhibit exploring how Earth’s denser atmosphere holds heat better than Mars’s thin atmosphere.

Special Note: The NYSCI has been temporarily closed since September 1, 2021 due to hurricane damage. Learn More