|

||||||

|

|

||||||

Thermoelectric Liquid chiller Applications |

||||||

COOLING DETECTORS FOR PIPELINE INSPECTION: The maintenance supervisor from an inspection company was experiencing over heating of his detectors which are used in his outdoor pipeline inspection process. TECA's TLC-900 Liquid Chiller was mounted to the back of his truck to aid in cooling two detectors. The components had been close to over heating without the chiller. Using the chiller with 50 feet of hose, the customer obtained a good result, successfully cooling his components down several degrees (Celsius), to a safer and more reliable operating temperature. The customer has purchased multiple TLC-900 Chillers for the same use in other trucks.

With little maintenance required, the TLC-900 has versatile features such as universal input (100-240 VAC), which is helpful in this application as the customer has inspections in Europe and in the USA. The same TLC-900 Chiller can be used in either locale. A PWM temperature controller offers USB communications, programmable ramp & soak profiles, and fan speed control for noise reduction. |

||||||

FLUE GAS ANALYSIS:

|

||||||

PRODUCTION TESTING ( COOLING DUT):

TECA’s RLC-1800 Rack Mounted Liquid Chiller offers powerful cooling as a component in the customer’s testing procedure. The customer, developing testing for a radar system, has a device under test (DUT) which contains cold plates. TECA’s RLC-1800 provides liquid cooling to the cold plates and prevents them from over heating during the process. The RLC-1800 is the most powerful liquid chiller we offer, with 620 watts cooling capacity. |

||||||

AIRBORNE THERMOELECTRIC LIQUID CHILLER:

|

||||||

|

Photofacial treatments using intense pulsed light are said to remove spider veins and age spots, but are uncomfortable for the patient.

|

||||||

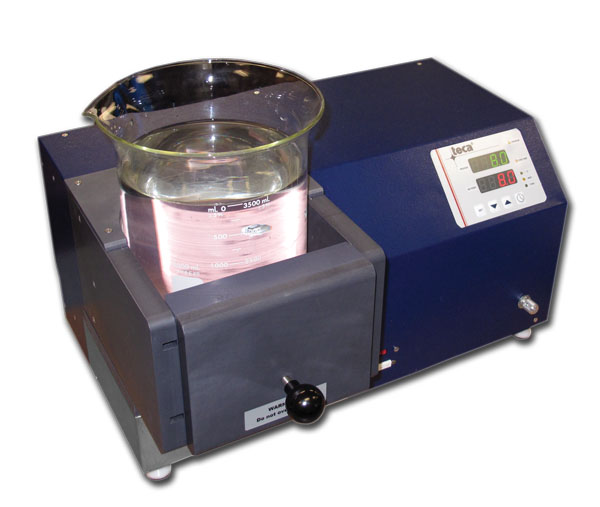

CHEMICAL VAPOR DISTRIBUTION SYSTEM: An OEM customer integrates TECA's Model TLC-900 Liquid Chiller into a bubbler system designed to distribute chemical vapor via a carrier gas. The bubbler vessel is filled with the liquid chemical. The carrier gas is bubbled through the vessel and TECA's TLC-900 Liquid Chiller maintains the chemical at a temperature determined by the end user, to maximize process control. The customer chose TECA's TLC-900 Liquid Chiller over others because of its heating and cooling capability and the versatility of its universal input voltage (100-240 VAC). The customer's system is sold worldwide and quality and reliability are key. The customer shared with us: |

||||||

|

A technological university in Asia chose TECA' s thermoelectric cooling Model AHP-800MSP Magnetic Stirring Cold/Hot Plate to anodize aluminum. The researcher's process required a temperature of 10C.

The AHP-800MSP's universal input voltage feature (100-240 VAC) allows it to be used anywhere, making it a perfect, off the shelf choice for our customer in Asia. He wrote to us: “It is quite good. Also the manual is quite clear and quite user-friendly. Thank you.” Unique to this product is the adjustable nature of many of its features: stir-bar speed, fan speed (for noise reduction), temperature sensing (internal or external) and more. The AHP-800MSP can even accept beakers of various size by adding optional sleeves. The solid-state thermoelectric construction is low-maintenance. There are no filters to change and no moving parts except for the fans. Our products use robust thermoelectric modules and boast a long service life. |

||||||

|

To chill liquids being circulated by a peristaltic pump under ultra-clean conditions without introducing contaminations is of outmost importance in laboratory applications. When handling and processing various fluids in laboratory and electronic environments cleanliness is a must. Peristaltic pumps have been developed for the purpose of creating a fluid flow without contacting the fluid itself.

TECA developed a liquid chiller to cool fluids, while satisfying the same cleanliness requirements. The solution, based on our successful cold plate product line, has proven to be versatile and effective. Pictured here is the first prototype of a multiple-pass tube cooler for use with a peristaltic pump. |

||||||

TESTING PROPERTIES OF MATERIALS:

A materials scientist at a state university uses TECA's TLC-900 Liquid Chiller to cool transducers for an elastic modulus apparatus. The apparatus measures the elastic modulus as function of temperature. The elastic modulus is a material property.

It defines the stiffness of material. It varies with temperature and is used in design. The customer uses the TLC-900 Liquid Chiller to cool a plate, which then cools from 400C to between 30C and 50C. |

||||||

SEMICONDUCTORS: A research oriented organization uses TECA's TLC-900 recirculating liquid chiller to control the temperature of a semiconductors test stage where proximity of TEC would produce electromagnetic noise hard to screen. Temperature controlled fluid supplied byTLC-900 keeps our test stage cooled and free of noise. |

||||||

LIQUID CHILLER COLD PLATE CASCADE:

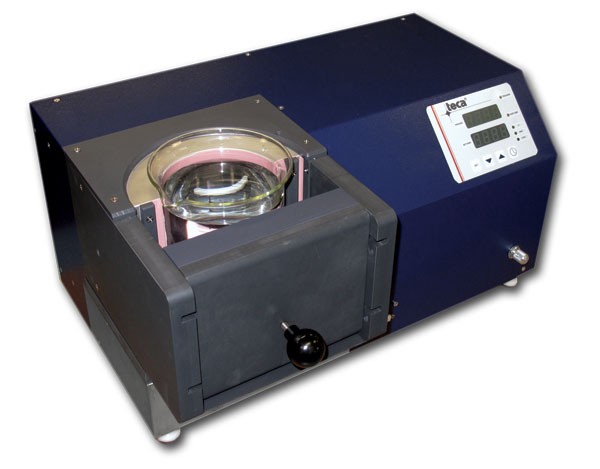

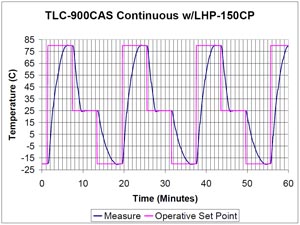

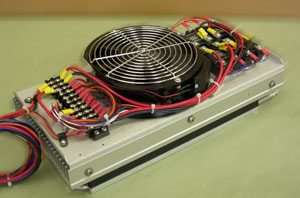

Here are pictures of the TLC-900 thermoelectric liquid chiller with LHP-150CP Peltier liquid cooled cold plate set up run in the lab. The “load” is a plate with 10 power resistors mounted to the top and a series of thermocouples measuring the surface of the LHP-150CP’s thermoelectric cold plate. During the test the power to the resistors is increased in steps with enough time in between for the temperatures to stabilize. Plotting the data resulted in performance curves. The test was made with the load insulated and with the load simply covered. Later on we used a TLC-900CAS, a version of the TLC-900 made specifically for running and controlling secondary cold plates like the LHP-150CP and ran some step, ramp and soak profiles. |

||||||

|

A commercial laboratory uses TECA Chiller TLC-1200HC to discourage temperature gradients in a calibration system.

Utilizing the built in temperature controller, the customer was able to successfully run the input and output to a temperature difference of zero. Designing a suitable calibration method was critical to the customer’s ability to release a new product to market. The photos here illustrate the compact size of TECA’s TLC-1200HC. |

||||||

CHILLING PROCESS INK: Here’s the way they’re all supposed to work:

|

||||||

CHILLER WITH 200' HOSE: A customer wanted a TLC-1400 thermoelectric liquid chiller (Peltier chiller) to maintain a 400 watt load under normal conditions except for one thing, the hose needed to be over 200’ long. Would it pump? How much of an effect would it have on the cooling capacity?

We could have run the numbers and come up with an estimate. It was really easier to just hook up some hose and a constant load plate, roll it into the environmental chamber and see what it did. It did more than it was supposed to. The customers safely bought it knowing it would do what he needed. |

||||||

BEVERAGE COOLING:

Here’s more of the engineers dream test job. The guys were messing around and decided to cool a keg with a TLC-700 liquid chiller and one of our medical customers water pads used for patient temperature therapy. Instead of the patient laying down on the pad they wrapped it around the keg and then insulated it. Not quite an economical way of cooling your beer. But they did use the mattress the next day to sleep of the hangovers. |

||||||

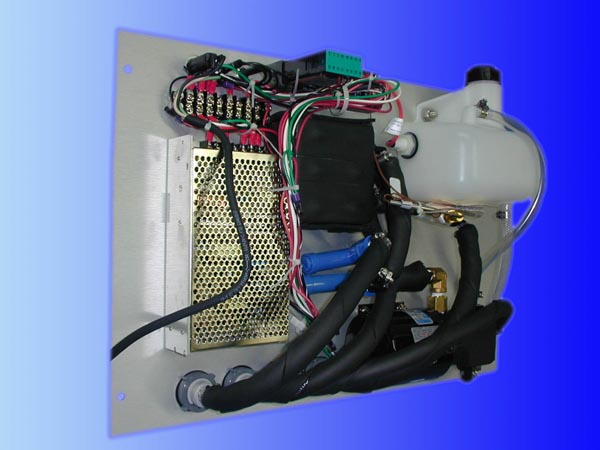

MEDICAL: Customer needed a compact thermoelectric cooling system to cool flow of fluid through removable membrane liquid jacket for mobile medical application.

TECA’s sales and engineering team worked with the customer and developed the product you see in the pictures above for the exclusive use of our customer. The application is medical and will be protected by patent. Thermoelectric cooling will be employed for effective cooling of the brain for emergency treatment of stroke victims. |

||||||

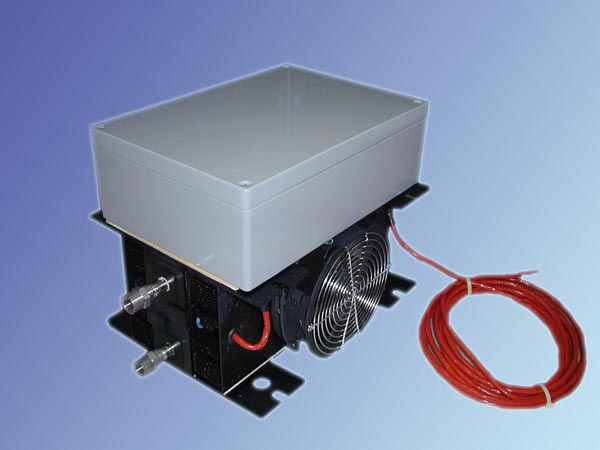

MILITARY: The United State Navy needed a liquid chiller to circulate coolant and also meet strict military requirements.

Here’s another custom military application by TECA. This is a liquid chiller for circulating chilled coolant as part of a tracking system on a NAVY ship. Note that the chilled liquid circuit is effectively “sandwiched“ between two heat sinks with rugged Mil 901 fans. Wiring and electrics are housed in a NEMA4X enclosure with an O-ring gasket seal. This unit is rated for shipboard use in salt-spray, shock and vibration. |

||||||

AEROSPACE MANUFACTURING: To meet a customer requirement TECA sales and engineering team modified a standard model chiller to meet a highly specialized demand of the application, including liquid cooling, 24 VDC input and wall mounting.

|

||||||

|

||||||

Catalog | Sizing Software | Manuals | Applications | Site Map | Privacy Policy | Testimonials | Contact © 2014 ThermoElectric Cooling America Corporation. All Rights Reserved. |

||||||