Design Considerations:

NEMA-12: Type 12 enclosures are intended for indoor use primarily to provide a degree of protection against dust, falling dirt, and dripping non-corrosive liquids. Applies to AHP & FHP models.

Source: NEMA Publication N0. 250, Part 1, Page 1

NEMA-4: Type 4 enclosures are intended for indoor and outdoor use primarily to provide a degree of protection against windblown dust and rain, splashing water, and hose directed water. TECA products with the “XE” designation use sealed fans, sealed components, stud/gasket mounting and Mil- Spec finishes. They are designed to maintain the enclosure rating and perform in the rated environment. Applies to AHP-XE & FHP-XE models.

Source: NEMA Publication N0. 250, Part 1, Page 1

NEMA-4X/Harsh Environment: Type 4X enclosures are intended for indoor and outdoor use primarily to provide a degree of protection against corrosion, windblown dust and rain, splashing water, and hose directed water. TECA products carrying the “X” designation use Mil-Spec fans, o-ring sealed power supplies, no exposed electronic components, stud/gasket mounting and Mil-Spec finishes. They are designed to maintain the enclosure rating and perform in the rated environment. Applies to AHP-X & FHP-X models.

Source: NEMA Publication N0. 250, Part 1, Page 1

Corrosion: (Salt Fog Testing) Method 509.2,168 Hours. Applies to AHP-X models.

Vibration: Method 514.3, 2 hours, x,y,z axis 8.9 G’s. 10-2000 Hz with a magnitude of 0.04 G²/Hz.

Applies to XM (consult factory) models

Vibration: Method 514.3, 2 hours, x,y,z axis 8.9 G’s. 10-2000 Hz with a magnitude of 0.04 G²/Hz. Applies to XM (consult factory) models.

Shock: Method 516.2, with 30 G’s peak amplitude, 11ms pulse duration, half-sine waveform, and three (3) shocks in each direction along three (3) mutually orthogonal axes. Employed for all XM versions. Standard models are designed to withstand 2.2 G’s.

Applies to AHP-1200X, 1201X, 1200XP, 1201XP, AHP-1800X, 801X, 1800XP & 1801XP models

Source: Mil-Std 810

CID2 Class I, Division 2 (Hazardous Environments) – a location (1) in which volatile flammable liquids or flammable gases are handled, processed, or used, but in which the liquids, vapors, or gases will normally confined within closed containers or closed systems from which they can escape only case of accidental rupture or breakdown such containers or systems, or in case of abnormal operation of equipment; which ignitable concentrations of vapors are normally prevented by mechanical ventilation, and which become hazardous through failure operation of the ventilating equipment; that is adjacent to a Class I, Division location, and to which ignitable concentrations gases or vapors might occasionally communicated unless such communication prevented by adequate positive-pressure ventilation from a source of clean air, safeguards against ventilation failure pro-vided.

Applies to AHP-XP models

Groups (A-D) Atmospheres containing following: acetylene, hydrogen, fuel, combustible process gases containing 30% hydrogen by volume, or gases of equivalent hazard such as butadiene, ethylene oxide, propylene oxide, acrolein, ether, ethylene, or gases or vapors equivalent hazard such as acetone, ammonia, benzene, butane cyclopropoane, gasoline, hexane, methanol, methane, naphtha, propane, or gases or vapors equivalent hazard.

Applies to AHP-XP models

Source: NEC 2005, Article 500

Applies to AHP-XP models

UL-1995 & CSA 22.2: Heating and Cooling Equipment, Categories 169 & 294, No. 236- M90. Tested thru ETL and ETLc Testing Laboratories, Report #532015.

Applies to the following air conditioner models: AHP-1200, 1201, 1202, 18001, 1801, 1802, 1501; AHP-1200XE, 1202XE, 1501XE, 1800XE, 1802XE; FHP-750, 752, 1501; FHP-750XE, 752XE, 1501XE

UL-3101-1 & CSA 22.2: Electrical equipment for laboratory use. Safety requirements for electrical equipment for measurement, controls and laboratory use. Tested thru ETL and ETLc Testing Laboratories, Report #20022721.001.

Applies to TLC-700, TLC-702 liquid chiller models

Low voltage directive 73/23/EEC – European Union (EU)

EMC directive 89/336/EEC – European Union (EU)

Tested thru ETL.

Applies to the following air conditioner models: AHP-1200, 1201, 1202, 18001, 1801, 1802, 1501; AHP-1200XE, 1202XE, 1501XE, 1800XE, 1802XE; FHP-750, 752, 1501; FHP-750XE, 752XE, 1501XE

EN 61326, EN 61010-1 & EN 61010-2: Application of council directive: Machinery directive (89/336/EEC)

Standard EN 61326:1997, Class A; EN 61326:1997, Industrial location

Low voltage directive 73/23/EEC – European Union (EU)

Standard EN 61010-1-A1:97; EN 61010-2-010-A1:97

Tested thru ETL.

Applies to TLC-700, TLC-702 liquid chiller models

TECA’s FHP thermoelectric air conditioners are designed to mount on the outside of the enclosure. There is no intrusion within the enclosure allowing for greater design flexibility. A mounting plate provides for easy installation.

Side, Front, or Back Mounting: This mounting orientation is recommended for applications with high humidity or incomplete cabinet seals. Condensation can be removed via moisture collection systems (standard on FHP-units and AHP-1400) or a drip pan positioned below the cold side fins. Drip pans are optional for thru mount style units.

Top Mounting: It is difficult to collect condensation in this orientation due to fin orientation and gravity. If a drip pan is employed by the end user, use caution to place the pan far enough away from the internal fan to minimize the restriction of air flow. The pan should cover the fin ends as well as the fan area. When there is a choice, side orientation is preferred by most users in high humidity environments.

- Regulate the fin temperature above the dew point. Equations are provided for this purpose

- Use desiccant (moisture absorbing granules)

- Employ condensate removal system or drip pans

FHP-Series and models AHP-1400, AHP-1501 Air Conditioners contain built-in condensate removal systems. The condensate system consists of an anti-fungal sponge with a condensate wick. PVC tubing is also provided for drainage. The wick should extend below the cooling assembly to allow for a gravity feed.

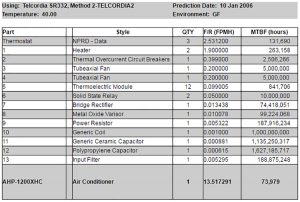

MTBF calculation was made using Telcordia SR-332, Method II.

Mean time between failures prediction ranges from 80,000 hours for ground benign, outdoor, 25C environment to 47,700 hours for ground mobile, outdoor, 70C environment.

On this website under “APPLICATIONS“, please also see the ongoing test of TECA Model AHP1800XEHC which has been in continuous service for over 80,000 hours outdoors on the roof. There is also a picture and description of a TECA Model AHP1200X with 120,000 hours of duty with no problems other than dirt!