Anodizing Aluminum:

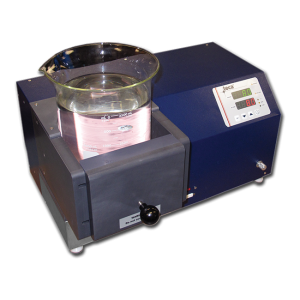

A technological university in Asia chose TECA’ s thermoelectric cooling Model AHP-800MSP Magnetic Stirring Cold/Hot Plate to anodize aluminum. The researcher’s process required a temperature of 10 °C.

The AHP-800MSP‘s universal input voltage feature (100-240 VAC) allows it to be used anywhere, making it a perfect, off the shelf choice for our customer in Asia. He wrote to us: “It is quite good. Also the manual is quite clear and quite user-friendly. Thank you.”

Unique to this product is the adjustable nature of many of its features: stir-bar speed, fan speed (for noise reduction), temperature sensing (internal or external) and more.

The AHP-800MSP can even accept beakers of various size by adding optional sleeves. The solid-state thermoelectric construction is low-maintenance. There are no filters to change and no moving parts except for the fans. Our products use robust thermoelectric modules and boast a long service life.