Best Practices for products in rugged industrial applications:

Harsh environments are not unique within industrial settings but the solutions for systems operating in harsh areas can be unique depending on the end user’s needs. Let us explore the best practices- and related challenges- when it comes to designing for industrial applications.

Nema Rating:

The National Electrical Manufacturers Association (NEMA) defines standard environment-types for electrical equipment. For example, standard devices used in a rugged application will require a protective NEMA-4/4X enclosure with active heating and cooling. Use ruggedized equipment when possible.

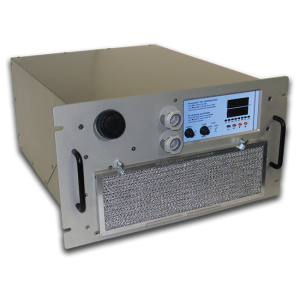

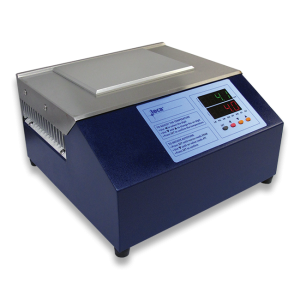

Related Challenge: Anytime equipment is added to an enclosure, power requirements go up. This includes power to any heating and cooling devices. Ruggedized equipment is not always possible. Sometimes, a protective enclosure is necessary. An efficient thermoelectric heater/cooler with a heat-exchanger mode will offer thermal management while adding the minimal amount possible to power requirements.

Shock and Vibration:

NEMA-4/4X outdoor cabinets, industrial manufacturing facilities, light poles, railroad tracks, intermodal stations, and vehicles are examples of places where equipment maybe subject to extreme vibrations and shock. Use products that can handle those extremes.

Related Challenge: Unfortunately, “shock & vibration” is a phrase that is sometimes used too casually. Shock refers to single pulses or movements. Vibration refers to a continual pulse or movement. When specifying equipment, research (or ask the original manufacturer if possible) whether each component in the equipment is suited for shock and vibration.

Power Requirements:

If the application environment has AC input voltage available, sorting out how to power your system is easier. Typically, in these cases AC to DC power supply can be used to power electrical components.

Related Challenge: Surveillance and network systems (for example, along a rail line) can vary in power requirements. Some operate on 24VAC, others 12-48VDC. If active heating and cooling is required, consider a thermoelectric air conditioner. The 12, 24, and 48 vdc configurations of such coolers cut down on cost.

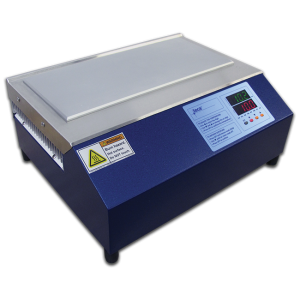

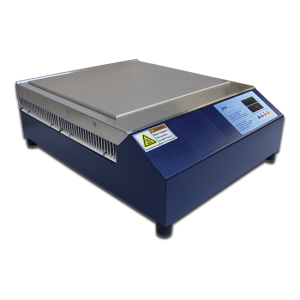

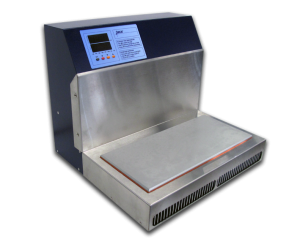

Active Cooling/Heating System:

An active thermal management solution will not always be required, as we have already seen. When it is, however, there are a myriad of important considerations: maintaining the NEMA-4/4X integrity of the enclosure rating, accounting for distance problems, and operating temperature range limits.

Related Challenge: Opening an enclosure to ambient air or using a fan or other device can mean ambient heat, humidity, and debris will enter your enclosure. Although cheap and at time effective, these solutions are too much a liability to be risked. Ambient exposure will shorten the life of your equipment! It is best to use a thermoelectric solution that is suitable for your enclosure type (NEMA-4/4X, CID2, Shock & Vibration, etc). Thermoelectric enclosure coolers maintain a closed loop system, can be operated remotely, and can work in extreme temperatures.

Learn more about thermoelectric cooling. Download our white paper now!