Cooling Larger enclosures Than Ever Before:

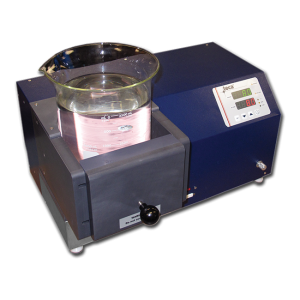

A user of the Model AHP-6250 Solid-State Air Conditioner gives a wonderful example of the benefit of TECA’s newly introduced line of high-capacity thermoelectric air conditioners.

Designed to cool larger enclosures than was previously practical with thermoelectric technology, the AHP-6250 is one of the largest models in this group. For example, the enclosure pictured here is about 8 x 6 x 3 feet. The customer is able to achieve large enclosure cooling with a single thermoelectric air conditioner. Thermoelectric cooling is reliable and maintenance free.

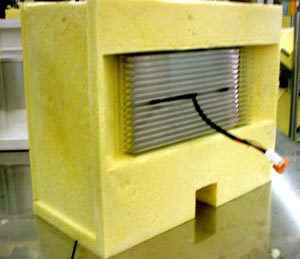

TECA’s new high-capacity line has some thoughtful design features, as seen pictured here on the installed AHP-6250. The cold side (internal to enclosure) has a low profile, which translates into less intrusion into the enclosure, giving the user more room for whatever the enclosure is meant to hold. The robust mounting flange, gasket and hardware and centrally located power input contribute to user-friendly installation. Finally, high air-flow fans and high fin-density heat sinks on the cold side maximize performance and minimize condensation. An integral condensate removal system absorbs condensation and transports it to the hot side, where it gets evaporated into the ambient.