Protecting PLC Equipment in a Hazardous Environment:

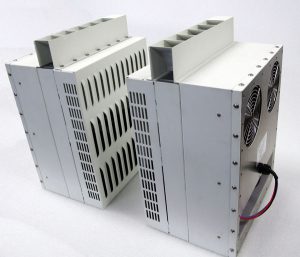

TECA’s legacy product, Model AHP-1800XPHC has been installed in over a dozen (to date) specialty cabinets by a process safety engineering firm.

Our customer shared with us:

“We asked a client for a preferred vendors for the thermo electric coolers and TECA was given to us. We have been pleased with the products and service your company has given.”

Our customer serves refineries and chemical plants, implementing critical safety control systems. With both outdoor and indoor needs, TECA Model AHP-1800XPHC can be used in either environment, and it can maintain a cabinet rated for CID2 explosion-proof. Among the sensitive equipment TECA’s enclosure cooler protects is a group of programmable logic controllers (PLC). The PLCs need to be reliable, safety certified, and able to withstand rugged conditions. The stakes are high in this application. The CID2 “Hazardous Location” enclosure coolers offered by TECA include safety certification, mil-grade external fan, and a decades-long track record with customer like this one.

Please browse our CID2 solutions here and contact us here to discuss your unique cooling needs.

Ph: 773.342.4900

Like all TECA “XM” units, the

Like all TECA “XM” units, the