Military Liquid chiller:

Here’s another custom military application by TECA.

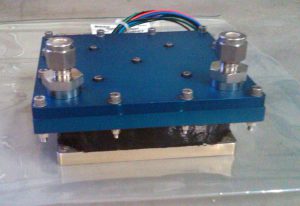

The United State Navy needed a liquid chiller to circulate coolant and also meet strict military requirements. TECA developed a custom thermoelectric liquid chiller using MIL rated components. This is a liquid chiller for circulating chilled coolant as part of a tracking system on a NAVY ship.

Note that the chilled liquid circuit is effectively “sandwiched“ between two heat sinks with rugged Mil 901 fans. Wiring and electrics are housed in a NEMA-4X/Harsh Environment enclosure with an O-ring gasket seal. This unit is rated for shipboard use in salt-spray, shock and vibration.