Cooling Gas FLow:

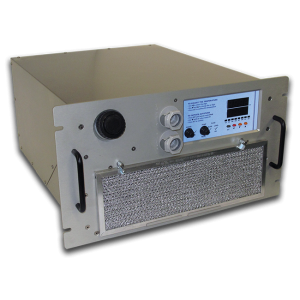

A potential customer expressed interest in a cooling/heating system for an aerosol flow tube envisioning a 1 inch OD, 0.875 inch ID stainless steel flow tube mounted inside a 2-2.5 inch ID pipe (likely also stainless steel and insulated on the outside) capable of controlling the tube at temperatures ranging from roughly 5 °C to 40 °C at an ambient temperature of 25-30 °C. We are measuring the change in particulates in the air due to the temp change.

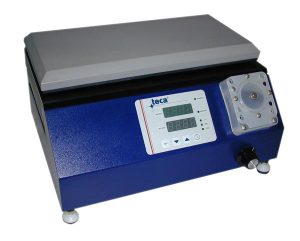

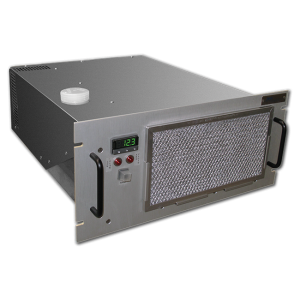

Standard liquid chillers were first offered along with technical design assistance. The requirements led to direct contact cooling as being a good solution. Standard cold plate products and controllers were offered which led to this request for a custom package. “We would like to have the flow tube sandwiched between the cold plates with the temperature controller and power supplies attached in a similar manner so that we only need attach the temperature controller (the TC-3400 appears as if it will work) to a computer so that we can change the set points remotely.

Is any of this even possible or am I dreaming in Technicolor?” We advised him that the best dreams were in color. Preliminary design work was done and a quote prepared. Shortly thereafter an order was received; design documents were completed and sent to production. Less than 3 months after the initial contact the product was shipped. Several months later a follow up was made with this response.

“Things are doing really well. It does exactly what we wanted it to do, and is much more efficient and better than we hoped for. We’re very happy!