Communications:

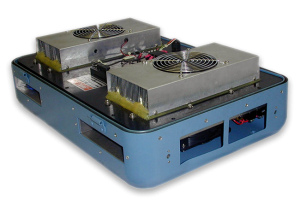

A major manufacturer of communications equipment was to go into production of special equipment enclosures, then encountered unforeseen problems with overheating electronics deep inside. The customer wanted air conditioning, but specified that no part of the air conditioner could protrude outside of their enclosure.

TECA designed a little air conditioner inside ducts for hot air exhaust. This way the air conditioner is actually housed entirely inside the enclosure and our customer continues production.