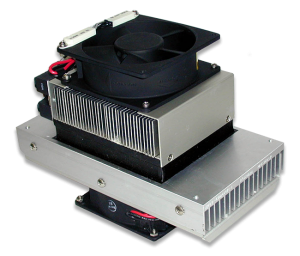

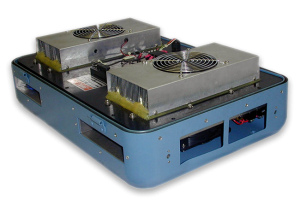

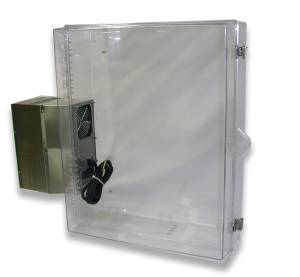

Safety Panel Cooling:

TECA provides standard off the shelf as well as custom designs to meet the needs of the end user. Alarm enclosures can be exposed to some of the harshest conditions like the extremes of live-fire heat and hose-down. The alarm enclosure pictured here is for fire safety and switches. The transparent plastic enclosure is accessible and secure while being cooled to desired temperatures under harsh firefighting conditions. In this example TECA provided custom modifications to provide for redundancy and mounting requirements specified by the end user.

Contact teca@thermoelectric.com to inquire about custom designs for your needs. Our friendly sales team looks forward to hearing from you!