Pharmaceutical Laboratory:

Keeping drugs cool on the bench

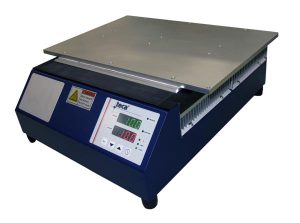

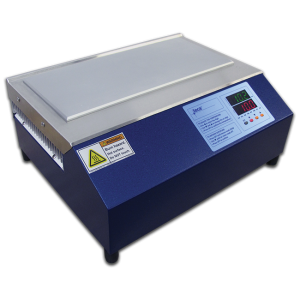

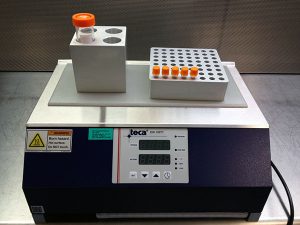

A private biopharmaceutical company formulates drugs that are sensitive to temperature. TECA Model AHP-1200 CPV is their perfect benchtop cooling solution. The customer uses the AHP-1200 CPV Cold Plate in combination with the customer’s own aluminum blocks to keep solutions at 0C during filtration and vial filling operations.

The customer reports, “We have been very satisfied”. This customer provided photo is a wonderful example of the versatility of TECA’s line of Laboratory Cold/Hot Plates. The plate surfaces are appropriately sized to accept microtiter plates and other lab accessories. The temperature can be read from either the plate surface or anywhere a remote sensor can be placed, via the Remote Sensibility™ feature.