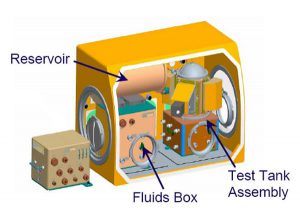

Beverage Cooling in a barrel:

Here’s an application that TECA’s engineering team was particularly excited about. Not because of the economics or the potential new business. Frankly we didn’t think the market was there. But as soon as they found out that a ½ barrel of beer would be needed for testing they were all over it. While none was ever sold, good lessons regarding contact methods and material stratification were learned. To see the result of the test click here.

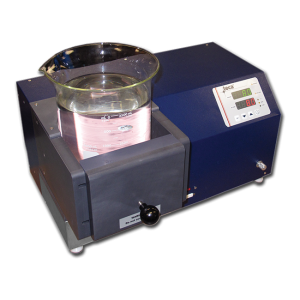

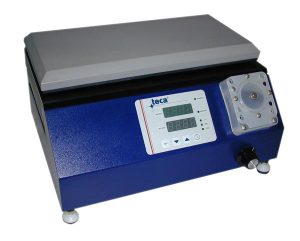

We used an AHP-1200CP thermoelectric cold plate and a TLC-700 thermoelectric liquid chiller for testing purpose.