Military Communications:

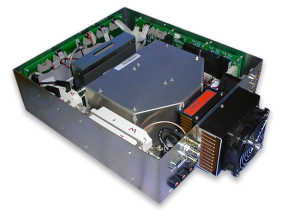

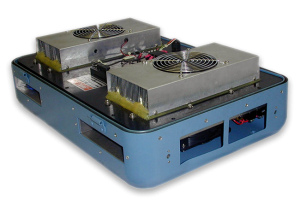

A branch of the US military had a need for cooling a small enclosure containing a critical voice communication system. The shipboard system had to be resistant to salt water corrosion as well as pass stringent shock and vibration testing.

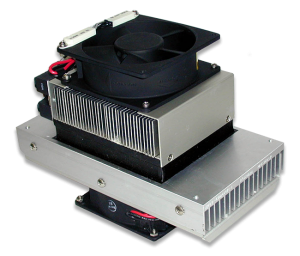

Modifications to TECAs AHP-300X solid air conditioner allowed the unit to meet specializing and air flow requirements and pass these tests. The challenge was to overcome the small available space both inside and outside the enclosure. The heat sinks were turned so that the heat rejection air flow and internal cold side air flow moved in different directions.

This unit is a prime example of how flexible Team TECA is when customer needs require customization of standard products.