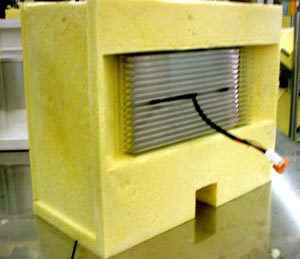

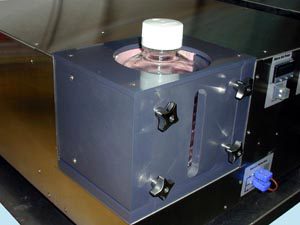

Fluid Dispensing:

A leading manufacturer of fluid dispensing systems uses one of our Thermoelectric Cold Plate and Temperature Controller for controlling the fluid temperature of adhesives, sealants, lubricants and other materials in meter, mix and dispensing systems.

Unlike other larger, higher cost and less accurate heating and cooling devices, which use heater cartridges, refrigerant or water to heat and cool, these thermoelectric-effect temperature controllers use the Peltier-Seebeck effect to directly convert electrical voltage to thermal differentials. This effect, which is reversible, either heats or cools fluid materials with precision to the temperature set point. The compact Peltier thermoelectric device, temperature sensor and the temperature control is mounted to a manifold where the fluid passes through to be precisely heated, maintained or cooled.