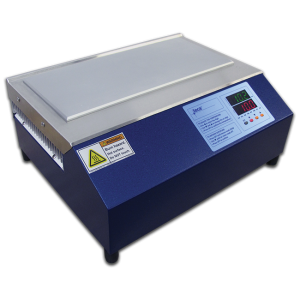

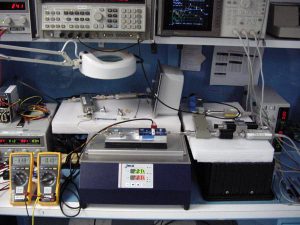

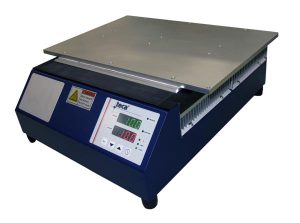

Electronic Test Station:

An aerospace contractor was interested in a large cold plate for the testing of electronic components. We first offered them the AHP-1200CPV but they responded that the AHP-1200DCP was more the size they wanted. Could we change it to a single plate? Well, we couldn’t change the plate size but we could add an accessory plate which was larger. And we could build the unit with one controller including all of the standard options.

Now they are using the 12” x 18” custom accessory plate and a special AHP-1200DCP to test electronic amplifiers by ramping the temperature up and down between +10 °C to +70 °C. A custom solution at very nearly standard product price to fill a not so unusual need.