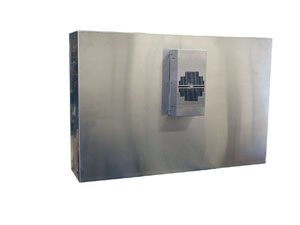

Ruggedized Military Application:

Sometimes it just takes a long time to get to the heart of a problem. AHP-1200X “quick quote” for two thermoelectric air conditioners came into our sales team. It was responded to and followed up. The application was reviewed, a quote was made and an order placed.

Only after did we learn that the hard requirements they were looking for were:

- Dual adjustable temperature control (heat and cool)

- 28 VDC operation and

- Military environment.

Fortunately the selections within TECA’s enclosure air conditioner family are large. The military Contractor borrowed a unit from TECA’s loaner stock and based on that success, placed an order. It was then that we found a problem.

It seems that the application was to cool some sensitive electronics out on a 200 meter DC input which caused droop in the input which in turn caused a ringing in the circuits. The new digital monitors being used were susceptible while the older tube monitors had no issue.

Working with the customer it was determined that by changing the controller to a ruggedized PWM controller all problems were solved.