Medical Laboratory:

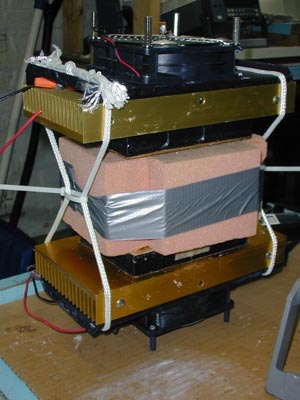

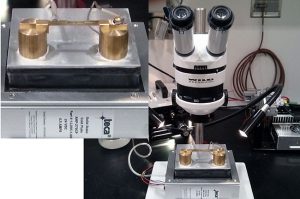

Department of histology in a major hospital needed a peltier cold plate to freeze tissue samples for examination. The Histology Division of the Department of Pathology places tissue samples from biopsies into a small block and fills it with wax. Several of these samples are then placed on one of the AHP-1200CP thermoelectric cold plates (Peltier cold plates) to “pull the heat” out of the wax so it gets really hard.

The near-frozen samples are then shaved down to the desired section (slice) using a Microtome (in picture). The thin sections are then placed in the water bath to warm up the remaining wax in order to remove it and then place the section on a slide for examination.