NeoGraft FUE Hair Transplant:

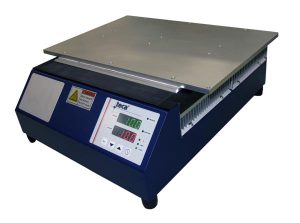

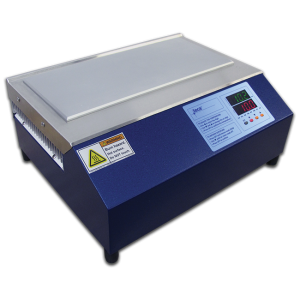

Our customer calls the ICE-160 Electric Ice Trays a “dramatic improvement”. He uses several in his medical practice.

From our customer: “We use the ICE-160 during the quality-control and graft-storage portion of our minimally-invasive hair transplant procedures. While hair transplant grafts are outside of the body, they are fragile and susceptible to damage from dehydration and other factors as they are separated from their blood supply. During this delicate phase of the hair transplant, the harvested follicular unit micrografts are now in a special physiologic holding solution at 4 °C using the thermoelectric ICE-160 before and after being counted and sorted and while they are awaiting implantation. This is a dramatic improvement over the use of traditional graft coolers using frozen water which need to be swapped out often during a long NeoGraft FUE hair transplant procedure.

We are confident that this method of graft storage ensures maximum graft viability and helps us maintain exceptional results for our hair transplant patients. The solid metal surface is simple to clean and disinfect after each procedure. Thank you for this great addition to our practice!”